Description of Formula Composition

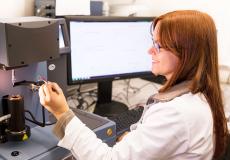

As, alongside the polymer, the remaining formula ingredients of a rubber compound have an important influence, it is desirable for users to describe or characterise a formula relating to its composition. A TGA (Thermogravimetric Analysis) facilitates this within certain limits. In the course of a TGA a material sample (approx. 10 mg) of the seal which is to be checked is heated continually until max. 1000 °C and the relative loss in weight over temperature is measured.

The evaluation of the formula allows a quantitative ascertainment of the compound ingredients in vaporisable ingredients (mainly plasticiser), pyrolysable ingredients (mainly polymer), oxidisable ingredients (mainly carbon black) and not oxidisable ingredients, also referred to as ash residue. In cases of doubt at subsequent supplies the compliance can be checked on serial parts if the graph has been recorded at an initial sampling. Therefore, this test is mainly performed for the initial sampling, for production monitoring only in cases of doubt or for crucial parts. A TGA-graph provides valuable information for failure analyses as well and often allows drawing important conclusions.

Expert Knowledge on Physical Analytical Test Methods:

Show PDF/download